Working together with FGD means to open up an access to :

A number of foundries of diversified cast materials

- EN-GJL-150/200/250 EN 1561, EN-GJS-400-15/500-7 EN 1563

- Expertise in selection of additives and modifiers to meet specific requirement of the castings: machining, temperature and performance...

A number of foundries with different molding techniques

- Traditional molding/tapping machines for small and medium runs

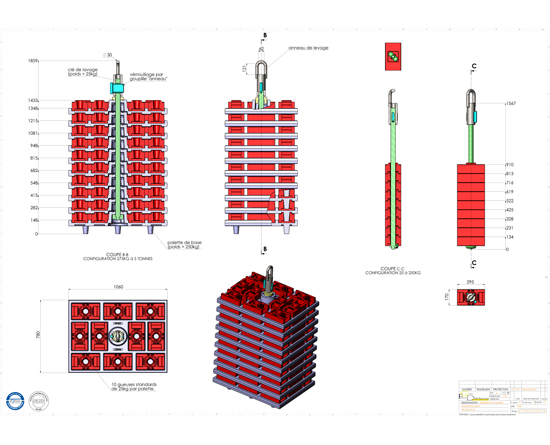

- Fully automated molding lines DISAMATIC type with vertical molds, unmatchable quality of the castings surface and dimensions : castings up to 200 kg with the frame/tool size 1200x1050 mm

- Manual molding on the shop floor: single, above standard production.

Integrated machining sections to limit the castings relocations from the casting process to the final assembly.

- Typical operations such as: drilling/milling/threading, turning, grinding...

Paint shop for the protection of the castings against corrosion and improvement of their final look

- Base coat according to spec

- Full palette of RAL colors in line with requirements, matching the master part.